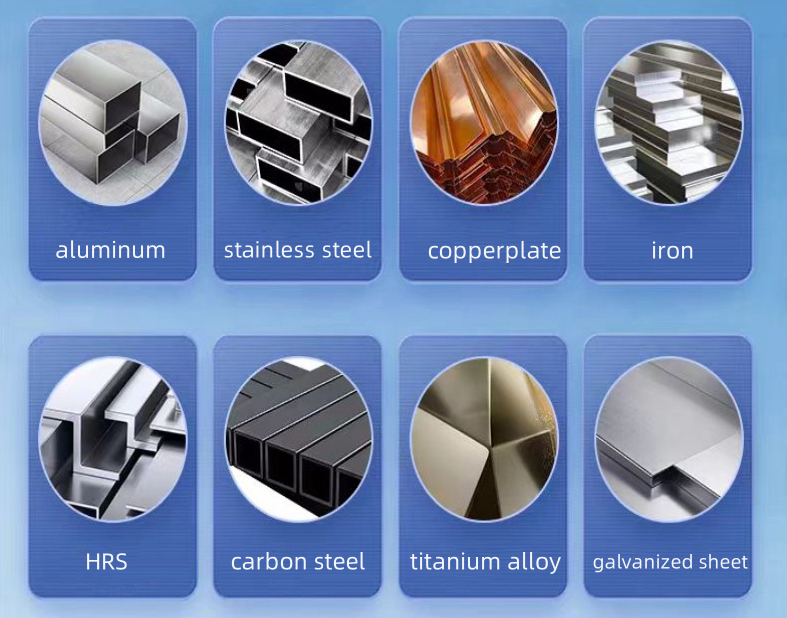

1. Simbi isina tsvina

Simbi isina simbi ine yakakwira coefficient yekuwedzera kwekupisa, uye inowanzoitika pakupisa panguva yewelding. Kana iyo inopisa-yakakanganiswa nzvimbo yakakura zvishoma, zvinokonzeresa zvakakomba deformation matambudziko. Nekudaro, kupisa kunogadzirwa nehandheld laser welding muchina panguva yese yewelding process yakadzikira. Yakabatana neyakadzikira yekupisa conductivity, yakakwira simba yekunyudza mwero uye kunyunguduka kwesimbi isina tsvina, yakanyatso kuumbwa, yakatsetseka uye yakanaka welds inogona kuwanikwa mushure mekugadzira.

2. Carbon steel

Ordinary carbon steel inogona kusungirirwa zvakananga nemaoko-akabatwaFiber laser welding Machine, mhedzisiro yacho inofananidzwa nesimbi isina tsvina, uye nzvimbo inobatwa nekupisa idiki, asi kana welding yepakati uye yakakwira kabhoni simbi, yakasara tembiricha yakakwira, saka zvichiri kudikanwa kuti weld isati yaiswa. Preheating nekuchengetedza kupisa mushure mekushongedza kuti ubvise kushushikana uye kudzivirira kutsemuka. Pano tinogona kutaura nezve inotonhora welding muchina. Simbi yepakati uye yakakwira kabhoni inogona kuvezwa kana kugadziriswa nekumhanya kunononoka neinotonhora welding uye yakakandwa iron welding waya. Panyaya yekudzora tembiricha, kudzora tembiricha, uye tembiricha yekudzora, inotonhora welding muchina unogona kudzidzisa ruoko-wakabatwa laser welding zvakanyanya kushanda pane yakasara yekupisa mushure mekutsvaira.

3. Die simbi

Yakakodzerwa nekubika mhando dzakasiyana dzesimbi inofa, uye iyo welding mhedzisiro yakanaka kwazvo.

4. Aluminium uye aluminium alloy

Aluminium nealuminium alloys zvinhu zvinoratidzira zvakanyanya, uye porosity inogona kuoneka mudziva rakanyungudutswa kana pamudzi panguva yewelding. Kuenzaniswa neyakapfuura simbi zvinhu, aruminiyamu uye aruminiyamu alloys ane yakakwirira zvinodiwa parameters, asi chero bedzi akasarudzwa welding parameters akakodzera , weld musono ane zvakafanana mechanical properties sezvo base simbi inogona kuwanikwa.

5. Copper nemhangura alloy

Thermal conductivity yemhangura yakasimba kwazvo, uye zviri nyore kukonzera kusakwana kupinza uye chidimbu fusion panguva welding. Kazhinji, zvinhu zvemhangura zvinopisa panguva yekugadzira welding kuti ibatsire welding. Pano tiri kutaura pamusoro pezvinhu zvitete zvemhangura.Ruoko-wakabatwa laser welding Machineinogona zvakananga Welding, nekuda kwayo yakadzika simba uye nekukurumidza welding kumhanya, haina kukanganiswa neiyo yepamusoro yekupisa conductivity yemhangura.

6. Welding pakati pezvinhu zvakasiyana

Muchina unobatwa nemaoko laser welding muchina unogona kuitwa pakati peakasiyana simbi dzakasiyana, senge mhangura-nickel, nickel-titanium, mhangura-titanium, titanium-molybdenum, ndarira-mhangura, yakaderera kabhoni simbi-mhangura uye mamwe masimbi akasiyana. Laser welding inogona kuitwa pasi pemamiriro ese (gasi kana tembiricha).

Handheld laser welding muchinaParizvino chigadzirwa chinoshandiswa zvakanyanya muindasitiri yewelding, kunyanya nekuti kunyangwe mudziyo uyu unotaridzika unodhura, unogona kuchengetedza mari yevashandi zvakanyanya. Mutengo webasa wevelder unodhura zvakanyanya. Kushandisa ichi Chigadzirwa chinogadzirisa dambudziko rekudhura uye kwakaoma kuunganidza welders. Zvakare, iyo handheld laser welding muchina wahwina kurumbidzwa kwakabvumirana kubva kuzviuru zvevatengi nekuda kwehupenyu hwayo hwesevhisi uye kushomeka kwesimba rekushandisa.

Kana iwe uchida kudzidza zvakawanda nezve laser yekuchenesa, kana uchida kukutengera yakanakisa laser yekuchenesa muchina, ndapota siya meseji pane yedu webhusaiti uye titumire email zvakananga!

Nguva yekutumira: Zvita-25-2024